In this hvac training video, i show how to use the charging jacket to measure the refrigerant charge on a heat pump or ac when the outdoor ambient temperatur. Usually indicates a blockage in the system.(i.e.

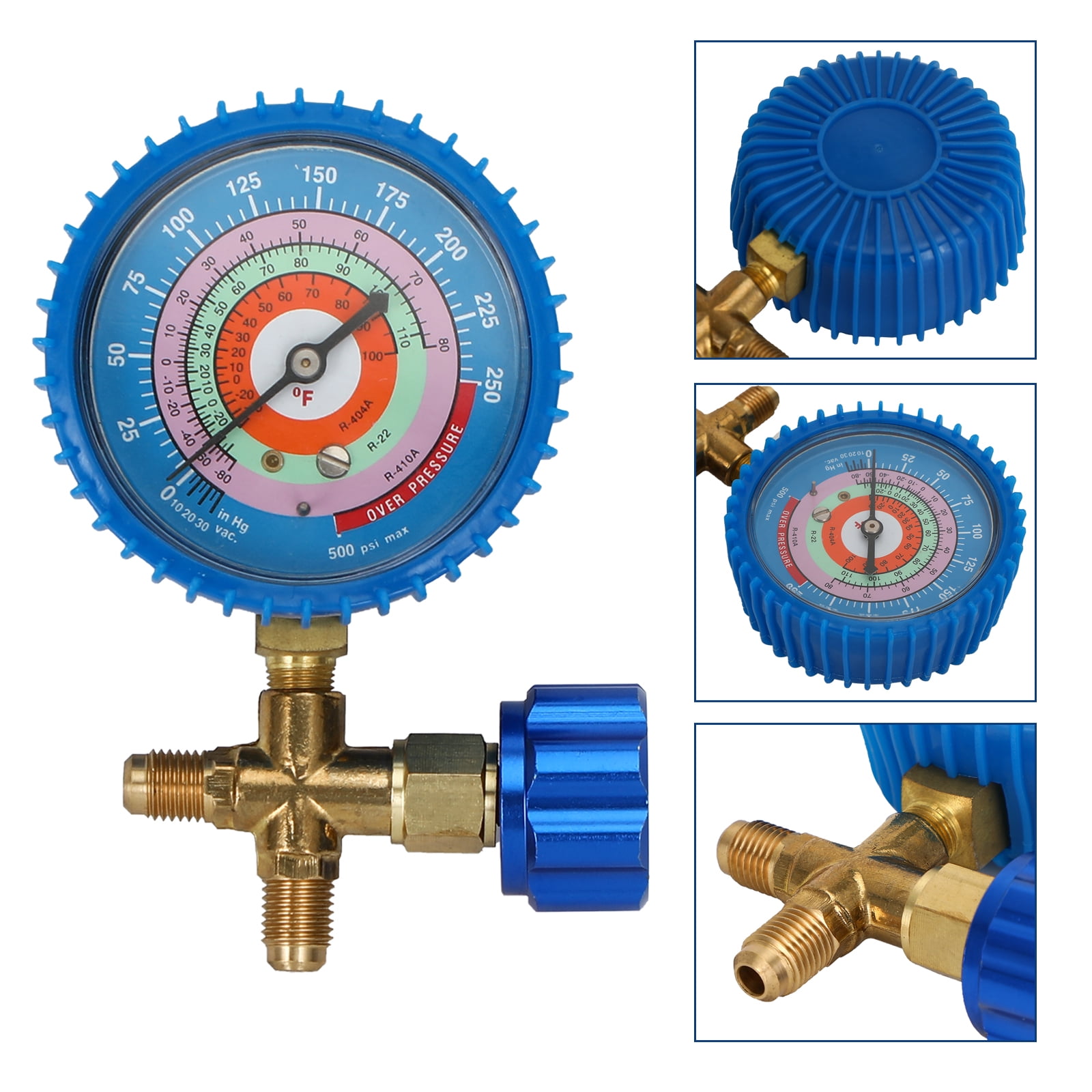

R410A R404A R22 Single Manifold Gauge 4 Testing Charging Air Conditioning Gauge - Walmart.com

Series 41 2 way manifold valve with 1/4″ ports.

The low side of the charging in testing manifold. Including increasingly refrigerant after weight testing will enable you to know which of these the reason is. Air conditioning charge & test manifolds; Due to the fact that the system is r404a i am charging on the liquid side.

Watch the gauges, adding refrigerant only until the vehicle manufacturer's specifications have been reached. I use a ball valve on my high side hose. Close low side valve on the manifold gauge set.

Charge system until gauges read over 50 pounds of pressure. An automotive air conditioner has a high and low side, divided by a metering device and the a/c compressor. Surieen r410a ac refrigerant charging hose kit, r410a r134a r502 r22 r12 r404a manifold gauge hose ac charging testing kit, with r410a straight swivel adapter, 1/4 male to 1/2 female tank adapter.

• low side pressure is low and high side pressure is high. Gauge is easy to read; 3/8″ large volumeplus ii™ hose.

Make sure the red hose can handle high pressure. When the engine is on. Series 41 manifold replacement parts.

Turn off high side and low side valves on the manifold gauge set. Opening the high side valve when the a/c compressor is running will damage the compressor. Connect the red hose to the high side port and the blue hose to the low side port on the manifold gauge.

Usually indicates a low charge. Low side pressure 50.55 psi high side pressure 340.345 psi Overview summary charging hose, gauge and low side manifold kit for mini split system installations.

Charging rate is up to eight times faster than vapor charging. A/c manifold test kit 50″ long hose high quality brass. Turn off the refrigerant gas canister supply.

Troubleshooting tips • low side and high side pressure are low. I am in the process of charging the system by weight to its full charge. Open only the low side valve on the manifold.

Simple low side charging manifold contains r410a rated low side pressure gauge. Yellow jacket® plus ii™ 21260 standard low side manifold hose, 1/4 in, blue, 60 in l To test the weight, turn the vehicle off and find the low side weight port.

• after charging, test the system by turning on the engine and running the a/c with both valves closed on the manifold. Before disconnecting i close the ball valve then open the low side valve on the manifold and all the refrigernat goes through the manifold/middle port and into the low side. Single low side manifold gauge with 1/4in.

Attach the kwik charge device to the low side of the charging manifold. The kwik charge charging unit accepts liquid refrigerant from the cylinder and discharges into low side of the system. It compresses and discharges it at.

In diagnostics, a manifold gauge tells an hvac technician if the system is operating correctly, or if there is a problem within the system that needs to be addressed. A manifold gauge set measures refrigerant pressures inside of an air conditioning system. Click to see full answer.

The low side weight administration port is commonly situated on the traveler side of the motor straight. • after testing, disconnect the couplers from the system and make sure to use a recovery/recycling machine to evacuate any refrigerant remaining in the hoses. Lightweight 1234yf charging manifolds and charging hoses.

Expansion of valve or orifice. Open the low side valve on the manifold gauge set. 2' long, blue hose with 5/16 sae connector for most newer mini split system service ports.

If there are readings on both the high and low sides but they are not. Open valve on the refrigerant source. Go to step # 4 in charging an a/c system that is low on refrigerant (below)

2' long, yellow hose with 1/4 sae connector fo Brute ii™ manifold replacement parts. However whilst i am charging (system is turned off) the suction side gauge on the.

9″ flexflow™ and low loss adapter hoses. When the engine is on and the ac is on high, low pressure readings should be around 30 psi and the high pressure side should be about 250 psi depending on your car. An automotive air conditioner has a high and low side, divided by a metering device and the a/c compressor.

The system was recently vacced. The correct reading will display once the clutch engages and the gauge stops cycling. Make sure to purge the middle hose the same way as you do the others, loosen the end and when you hear psssss tighten it.

Yellow jacket® plus ii™ 21260 standard low side manifold hose, 1/4 in, blue, 60 in l. When the low side is high, and the high side is low, the compressor is not functioning properly. The low side valve is closed.

A manifold gauge set measures refrigerant pressures inside of an air conditioning system. Hi all, a quick question i am currently charging a medium size dorin compressor for a cold stor application. They are one of the most basic hvac tools, and can be used as both a diagnostic and service tool.

Turn the equipment service valve in. You have new quote information.

Allow the pressure to increase to 1.5 times the normal operating pressure. Then testers hold the hose under water for at least one minute while looking for bubbles.

Brass Refrigerant Testing Manifold Gauge W/ Hose And Attachable Hook - Testing, Charging, And Evacuating Air Conditioning - R12 R22 R404A R134A | Lazada Ph

The least expensive and most common type of recharging kits are freon cans.

Air charging hose testing. In my book just needs a recharge: Risk leaving a leak at the schrader cores and caps The purpose of this test is to.

Watch the gauge on the refrigerant hose and check to see if your pressure is under 40 psi. The hack mechanic™ guide to vintage air conditioning, i make the case that those “a/c recharge $79.95” signs you see at service stations are perilously close to fraud. You want the reading as close to 40 psi as possible.

When you test your hoses, a hose rupture can occur. When the vacuum holds, the plant is ready for charging. These are just ball park number ranges to get you close, units should be charged in accordance with.

One minute, visually inspect hose and couplings for any leaking or unusual conditions. Couple a refrigerant cylinder to the liquid line charging valve, making sure that the cylinder is slightly tipped towards the head, and that it is lying the correct way for the bent internal discharge pipe to be at its lowest point. When a clutch comes loose or a hose breaks while under pressure, a hose can become wild.

Make sure you get air out of your refrigerant gauge hoses before charging a air conditioning unit. Adherence to best practice in service, maintenance leak testing and repair can significantly reduce refrigerant losses. This results in the following dangers:

Accurate and repeatable measurements for reliable results of leak testing A hydrostatic test uses water at a higher pressure inside the hose to verify the structural integrity of the end weld connections. Unit 3, the crosshouse centre, crosshouse road, southampton, so14 5gz (all telephone calls are recorded)

Until the pressure on the hose is adjusted, it is a great danger. Impulse testing for hydraulic hose is one of the key predictions of hose life. Surieen r410a ac refrigerant charging hose kit, r410a r134a r502 r22 r12 r404a manifold gauge hose ac charging testing kit, with r410a straight swivel adapter, 1/4 male to 1/2 female tank adapter 4.3 out of 5 stars 62

Checking the system (and charge) without gauges. Frequent testing at a too high test pressure is destructive and can result in the connection between the inlays and the hose being broken. Impulse testing involves the pressurizing or cycling of hose pressure, often times up to 133% of working pressure, at rates up to 1 cycle per second while the hose is held in either a 90° or 180° configuration.

Instant access to charge air cooler (cac) application experts. A leak test is performed to identify weak spots as well as to improve product design. Hold pressure at the working pressure long enough to check for leaks and perform any measurements.

If a system needs to be recharged, it’s because the refrigerant has leaked out, so the leak first needs to be found, then needs to be fixed. In generally they usually work the same way across the. Leak rates do not have to be this high.

We get more accurate readings when we connect gauges, but we also: Identify the weak spot of a pressure component. With the air bleeder open, the pressure shall be raised gradually to 45 psi (± 5 psi) (3.1 bar ± 0.35 bar or 310 kpa ± 35kpa) 12.

Reduced time to market and new part introduction. Immediate response with full design support. Make sure charging hose connections are secure.

After the hose test layout is full of water, all the air in each hose line shall be exhausted by raising the discharge end of Shorter lead times for ‘at speed’ and ‘on time’. Meet budget targets for lifecycle cost of product.

Benefits of goodflex charge air cooler (cac) hoses. Conditions appear contact the appropriate person for disposition of the hose. Testing the integrity of the hose to the outside, i.e.

To pass the test, the hose must meet or exceed two. Feed a small amount of refrigerant through the gauge test line and the charging line to purge any air. My question to you is, what do you think is in a system that has a leak and all of t.

Then inspect the hose and couplings for tightness. [note that newer test equipment may provide other solutions for this step to avoid releasing any refrigerant to the atmosphere.] then tighten the connection of. This guide shows you how.

Always make sure you follow the specific directions on the ac charging system. The pressure test must take place with water with the hose outstretched. Benefits of leak testing ac hoses with tracer gas.

For those of you worried about using compressed air because of moisture. The test is performed by using high pressure to check if there is a pressure drop caused by an unintended crack or hole. These often come with small hoses and gauges attached for an easy diy job.

Check if refrigerant may leak to the outside by charging both lines with helium and detect the presence of helium in the vacuum chamber. Risk contaminating the system with moisture and air; Particularly when the hose is large in size or when a part is still attached.

Determine min and max burst pressure.