Grab yourself an assortment of crystals, a bit of wire, and prepare to b. See more ideas about wire crafts, wire art, wire sculpture.

Rusty Metal Pole Wrapped In Barbed Wire Against Blue Sky. Close-Up. Copy Space Stock Image - Image Of Barbwire, Outdoor: 161615447

Spin the tool around the horizontal wire, and it wraps the wire as you go.

Outdoor wire wrapped in metal. It also is suggested that the nuts are wrapped lightly with electrician's tape for added safety and neatness. Vintage black metal wire votive tea lantern candle holder. Bx is safer than nm since the metal armor protects well against accidental penetrations.

This is one of my first wraps, and it’s pretty sloppy. It’s time to add the “metal band” to the stool. Stainless steel mesh filter discs (54) stainless steel mesh filter baskets (41) stainless steel mesh coffee filter (48) sink strainer filter (34) bbq smoke generator (70) sprouting jar lids (33)

Nm cable's vinyl sheathing is easily penetrated. If you wish to use flexible metal conduit, be sure it is watertight. Other helpful tools that go hand in hand with wrapping include pliers, mandrels, files, and jigs.

The horizontal wire rides inside the bend while the wire you’re wrapping around it gets pushed around via the notch in the tool. For this project, you'll need: Wiring in pvc conduit must have at least.

Participants will attempt to shoot 3d whitetail targets through a forest of steel tree obstacles to test their skill. The national electrical code has specific regulations for how many conductor wires can fit within a conduit of each diameter size: Make sure you have a snake or fish tape long enough to go from end to end.

Intermediate metal conduit, electrical metallic tubing. A white negative wire that is wrapped with paper. Heavy cast metal is used for switch boxes that will be mounted outdoors.

In this example of wire wrapping, a round, polished stone bead is used as the centerpiece and is wrapped in an inexpensive brass wire. Type uf cable is the most commonly used nonmetallic cable for residential outdoor wiring runs. Several common types are landscape lighting wire, sprinkler system connections, bell wire (for doorbells ), speaker system wires, and thermostat wires.

Most of these supplies should be available at your local hardware or craft store, or even online. Let the whitewash dry completely before moving on to the next step. Outdoor lantern string lights cafe lights 20feet with 12 clear g40 bulbs and vintage metal lamp shades, indoor outdoor lights for patio yard decor garden gazebo backyard hanging decorations.

This simple but beautiful suncatcher is a fun and easy start to your next obsession! Use a wide brush to make the work go quickly. The boxes, connectors, and conduits form a wire enclosure system called a raceway.

See more ideas about wire sculpture, wire art, wire crafts. Yes, they can be used outdoors, it is better to be safe than sorry. Outdoor use bbq wire net 304 stainless steel barbecue grill wire mesh.

Wire wrap is an electronic component assembly technique that was invented to wire telephone crossbar switches, and later adapted to construct electronic circuit boards. Cable refers to two or more wires encased in a protective sheathing. See more ideas about wire jewelry, wire wrapped jewelry, jewelry inspiration.

So you start the wrap by hand, and then engage the wire with the tool like so. You can easily tear off the wrapper after stripping it. Nonmetallic (nm) cable, sometimes called romex, has two or three insulated wires plus a bare ground wire all wrapped together in.

You still want the wood grain to show through. (this is also the main reason why only metal boxes may be. Some of the most reviewed products in armored cables are the southwire 8 ft., 12/2 solid cu mc (metal clad) armorlite modular assembly quick cable whip with 137 reviews and the southwire 3/4 in.

• easily attaches and ties down camping and hunting gear without tying knots — just twist the ends. Glue or fasten the pipe together with approved fittings and adhesives. Layout the pipe run adjacent to the trench.

Perfect for camping, backpacking, hunting, and more, the gear snake cord won’t rust, slip, or stretch. Electrical wire encased in flexible metal conduit. Usually ships within 3 to 4 weeks.

The absolute basic materials you need to begin wire wrapping are wire, a cutter and something to wrap. When using any non metallic wire outdoor, including romex, it is a good idea to run it through a conduit. Wire sizes range from about 22 gauge to 12 gauge.

Cable packaging indicates the gauge and number of wires. Briolettes, cabochons and gemstones are ideal for wire wrapping, but with some planning and creativity, you can wire wrap almost anything. Gather your wire wrapping supplies.

According to the nec, you can bury it at a depth as shallow as 6 inches. Wiring buried inside rigid metal (rmc) or intermediate metal (imc) conduit must have at least 6 inches of earth cover; A raceway is an enclosed conduit that forms a physical pathway for the electrical wiring to follow.

What are the shipping options for armored cables? Bx is heavy and difficult to run through studs. Electronic components mounted on an insulating board are interconnected by lengths of insulated wire run between their terminals, with the connections made by wrapping several turns of uninsulated.

Not only is nm cable light, but the slippery coating makes the cable easy to pull through holes in studs. Owing to the durability of rigid metal conduit, you can bury electrical wire in this conduit at a shallower depth. Youth archers wrapped competition at the gator cup with outstanding shooting in elimination matches in some intense sunshine, heat and breezy winds.

Trying to install 2 bulb ceiling light. A quick video showing you how to wire a motion sensor up to an led light.motion sensors are great in areas where a light switch is not practical.

Connected both black wires from fixture to black wire in ceiling box and both white wires from fixture to white wire.

How do wire insulation sensor in ceiling fixture. You can find out more information about the cost of rewiring in this householdquotes guide. It should be 48” from the floor. Lower the fixture base and remove the electrical tape or wire nuts from the black (hot) wire, white (neutral) wire, and, if present, green (ground) wire.

#4 · jun 3, 2009. Before doing any electrical work, always shut off power to the house at the main breaker. Yes, thermal protectors can go bad, but it is rare.

Look inside the recessed lighting fixture to locate the wing nut on the sidewall of the fixture. Trace the electrical box for the switch and. The white wire on the new fixture attaches to the white wire in the junction box in the ceiling.

Rotate several times with the tool in order to strip the pvc housing. I’ve done lots of knob and tube wiring in my early days. How to identify and repair light fixture wiring problems.

This only seemed to extend to just. Thin sheet metal may also be used to create barriers around attic fixtures. Twist the end of the motion sensor’s copper ground wire together with the end of the junction box’s copper ground wire.

There are two options for getting the wire from the ceiling and into the wall. Wave the flame from a lighter under the heat shrinkable tubing. Costs start at between £1,900 and £3,000 for a one bedroomed flat and go up to between £4,400 and £6,500 for a five bedroomed house.

The original unit in my ceiling fixture used a threaded nut, like a strain release, to attach the unit to the junction box. Connect the wires to the jacks and patch panel. Also you could luck out and have 3 conductors plus ground in cable going from switch to fixture box.

Make sure the lamp in the light fixture is dimmable, such as an incandescent bulb, or a dimmable led replacement lamp. This works great, but you will probably have to get into the attic (or make a much larger access hole) to get the drill level while drilling. Testing electrical wiring can produce different results depending on the method, so it is best to test each insulated wire to ground, one at a time, and then test between the two insulated wires, typically black and white for 120 volts.

The problem is that the insulation on some of the wires is brittle and falling off. If you have large diameter piping such as ducting, it can be used as long as it allows for the minimum. Wait for the superglue to dry completely.

If not, you can probably get into the attic and replace the wire. How to replace a ceiling light fixture turn off the power. Connect the black wire on the new light fixture to the black wire in the ceiling box.

Place the touch pad in a convenient location and make sure the switch on the light fixture is in the on position and the touch dimmer is ready to use. There is no need for additional wiring. Mount the motion sensor on the junction box using the provided hardware.

The plastic covering was crispy like it had been heated and cooled several times and cracked when bending the wire. I recently went to replace a ceiling light fixture in our great room. The hot wire was the same.

One of the best features of an incandescent bulb is its ability to turn electricity into heat. Do not disconnect the wires to the socket. I could be wrong, so test the wires in the ceiling fixture box first before anything else.

Determine a location for the light switch. It was very difficult to remove given that you have to work through the relatively small hole in the ceiling. Pinch each wire and ensure that the insulation is still good.

Those incandescent bulbs are inside a glass globe. Trace the mounting box on the ceiling where the light fixture will be mounted. No box is fairly common for older homes that i’ve worked on.

Unscrew the screws or nuts holding the fixture base to the ceiling box. Voltage readings for light fixtures. Required tools and materials (and costs) step 3:

You would need the manufactuer's name and catalog number of the recessed can to get a replacement. Secure the 2 copper ground wires together using a wire nut. The wing nut holds the socket and socket bracket in the fixture.

Removing these wires and creating a color to color splice or matching the original terminal wiring configuration, then adding the wires from the new fixtures and installing a wire connector should work. This replacement uses a spring clip to snap into the junction box hole. Let the socket and socket bracket drop from the fixture.

Remove the light bulb cover and bulbs from the fixture. Am experiencing a problem with connection. Measure and run the cables.

Hold the insulation in place and slide on a short piece of heat shrinkable tubing. Easy way to strip wire with super glue. Twist a wire nut over the ends to secure them together.

Attach the new light fixture, install. The original fixture was wired using the sets of screws as terminals or a junction. Keep the flame moving so the heat does all the work and the tubing doesn’t burn.

The light fixture in my kitchen needs to be replaced and when i took it down i discovered that the set up has three cables coming into the box that are tied together and has two wires coming down to the fixture. In this case, the installation is as easy as: Now, use your own wire stripping tool over the midsection of the dried glue.

The cost of rewiring your home will depend on the size of your house. Upon removing the fixture, i noticed that the neutral wire insulation was brown instead of white. The switch for the overhead light fixture will interrupt the power on the black wire.

Cut out the traced hole with an oscillating saw. These things are not generic, go back to the manufacturer to get a correct replacement.

When the electricity is turned off, the wires and connections cool down and contract. To have aluminum wiring in a residential setting.

Suneducationgroup.com Aluminum Metallic Heat Shield Sleeve Insulated Wire Hose Cover 19Mm 3Ft New Motors Car Tuning & Styling

Aluminum wire connections can overheat enough to start a fire without ever drawing enough current to trip a circuit breaker.

Can aluminum wire be heated. Solid aluminum wires are particularly unsafe, causing hazard conditions like arcing, which can cause a house fire. Aluminum wire expands more than copper when it heats up. Aluminum electrical wiring information for your website:

Solid aluminum wiring is a recognized fire and safety hazard. The ontario electrical safety code allows the installation of aluminum wiring. One of the issues with this type of wiring is that it expands three times more than copper does.

My water heater is about 30 yrs old and is 240 volt and has a 19amp rating. Www.cpsc.gov / www.saferproducts.gov, updated june. Any devices used must be approved for use with aluminum wire.

Force and ultrasonics are vital to the formation of aluminum bonds. When metals rust, they form an oxide on the. Aluminum has long been used for electrical wiring, but mainly.

Today, americans homes draw more electrical current through these aging circuits. This can result in overheated plugs. The cost of aluminum wire is about half that of copper, and that affordability can make a substantial difference is why aluminum wiring is a popular choice for the power grid.

Repairing aluminum wiring, us cpsc publication 516, u.s. The cause of the cable heating during operation is as follows: This equates to a resistance of 50 ohm.

Aluminum wiring itself is safe, if properly connected and terminated without damaging the wire. This value is confirmed by the slope. Aluminum wire is safe when the materials and methods of installation are correct as described in this list:

The symptoms of problems with aluminum wire include flickering lights and signs of overheating, such as burned insulation or oddly warm cover plates. Electric range, a.c., water heater)? For information on aluminum electrical wiring that can be copied to your website, see aluminum wiring summary page for public use.

The terminations need to be rated for aluminum wire, which can be problematic. Aluminum dissipates heat very quickly but can become permanently changed if heated past a certain point, approximately 750°f. All the expanding and contracting will eventually open up a gap, exposing the wire to air.

The bar will bend the metal to the desired shape. First, it is vastly improved in terms of the alloy composition today, versus 30 years ago. Aluminum wire bonding is a process similar to gold wire bonding but with the critical distinction that the surface does not need to be heated to 150°c or even anything above room temperature.

The insulation type must be approved for the application. Cable conductor resistance does not meet the requirements, causing the cable to generate heat during operation. I was told that there is aluminium wire running to my water heater from the breaker box that need to be replaced because its a fire hazard.

Consumer product safety commission, bethe3sda md, website: Place it on the pins and start bending the metal. Completely rewiring your home isn’t practical in most situations—it means tearing into walls and ceilings.

Neglected aluminum wiring can be a fire hazard to your home. Aluminum wiring can increasingly become defective at a higher rate. In other words, it has a much higher rate of thermal expansion.

However, it was discovered that the properties of aluminum were inherently different from copper. It can overheat more easily than copper and start electrical fires by slowly damaging its insulation and heating things around it. Purchased a new home il louisiana in 2006 (newly built on purchased lot) and now discovered that the 220v.

Aluminum is an excellent electrical conductor — ignoring the precious metals, it ranks right below copper on the conductivity chart. More work is now needed to prepare and later properly. The conductivity (sigma) of aluminum is 10 6 s/m.

Overloaded convenience circuits may exacerbate the issues associated with older solid aluminum wiring. The device has high strength, so you can fix the sheet of metal with a jack and give it a certain shape, even if the sheet is thick. Power cable through a certain load current, it will certainly fever, with the load current increases, the higher the cable surface temperature, if not treated, the consequences can be imagined.such as polyvinyl chloride (pvc) cable, core temperature is 70 degrees as the upper limit of consideration, the surface temperature will be.

Is this permitted anywhere in the country for 220v. When this occurs the aluminum wire can heat up further creating a fire hazard. Called the permit section of the local government and they act as if it’s o.k.

Wire and cable overheating causes and solutions! Aluminum wire must be installed properly. Aluminum wiring is no longer used for interior wiring systems.

Safe practices when installing aluminum electrical wiring. Yes, aluminum wire is permitted, for several reasons. The resistance of the wire is given by, r =l/σa r = l / σ a.

Solid aluminum wiring has many downsides, including rust and creeping. This wire creeping resulted in loose connections and overheating. The repeated expansion and contraction as the wire heated up and cooled down caused to the wire to creep out from under the terminal screws that held the wire in place.

The resistance of the wire can be calculated from its dimension and conductivity. This is how aluminum wiring can cause fires. But an electrician can make the connections safe by adding a short section of copper wire to the end of each aluminum wire.that way, copper rather than aluminum will be connected to each switch, outlet or other device.

When working on a dent at the center of an aluminum hood, less desirable units with wire grounds require two exposed metal areas near the edge as ground points. Take a jack and place a sheet of aluminum on the telescopic bar that comes in from below. Also, there are many more terminals used on equipment that will accept an aluminum conductor.

Wire and cable overheating reasons and solutions! The creation of an aluminum wire bond is the same as for gold wire, which consists of two attachment points and a specific. Because of the price difference, many people choose aluminum wiring over copper to cut the.

The wire gauge of aluminum wire must be sized sized correctly.

It varies for several reasons, but you generally need 1 awg copper wire for a 100 amp sub panel. Unless you can fly and land on the wire like a bird, you are very likely to be shocked and even electrocuted by touching an overhead power line to your.

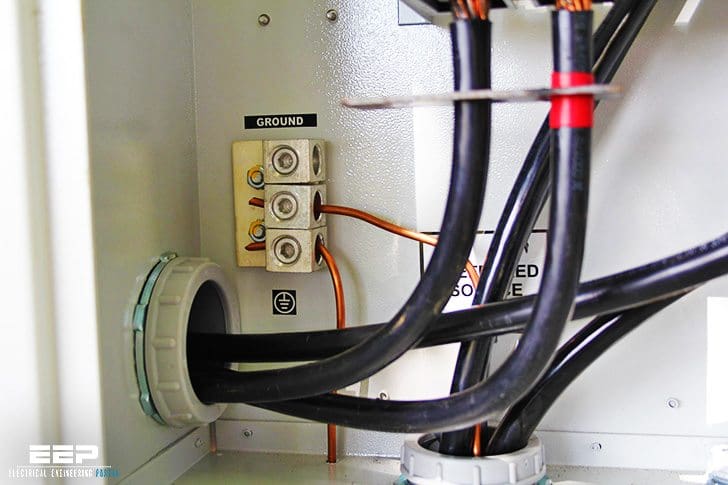

Practice For Good Grounding And Bonding A Home Wiring System | Eep

Drill destination hole in floor.

/number-of-electrical-wires-for-conduit-1152860_hero-39f793eb1a64424192912e7dc5620b50.jpg)

House feed wire by the foot. Its applications are outlined in article 340 nec 2008 and nec 2011. The size of the primary conductor may need to increase for a variety of reasons, including the length of the run, available fault current, or any number of reasons. Electrical wiring is rated in gauge for its size and amp rating.

We are a team of dedicated professsionals providing. Through strategic shipping locations and partnerships, our aim is to help our customers' operations come in on time. The nec is a safety guide.

The cable is sunlight resistant and is approved for use in accordance with the recommendations of the national electric code in raceways and underground installations. In chapter 9, table 5a of the 2020 nec, #2 aluminum. Top sellers most popular price low to high price high to low top rated products.

Feed the wire through the back of the outlet box, insert the box in the wall, and mount it in place. Superior customer service, affordable prices and fast delivery times. There is the need to build the physical.

Maximum operating temperature is not to exceed 90°c in wet and dry locations. Aluminum mobile home feeder cable is designed for mobile homes as a service entrance cable. Feed the fish tape through the conduit.

Lengths of wire vary from standard cuts of 50, 100, 250, 500 and 1,000. Loop the wires through the fish tape and wrap them with electrical tape. Intended for the connection of mobile homes to a supply of electricity where permanent wiring is required.

Stretch out the cable and untwist any kinks in it. Sunlight resistant, moisture resistant and flame retardant insulation. For amateur craftsmen, building a new structure can be an interesting challenge.

The minimum size for a grounding wire for 200 amp is #4 awg copper or #2 awg aluminum, according to article 250 of the 2020 nec. The first number denotes the conductor’s gauge; Short sections (≤ 5) should connect to a bigger section.

This cable also contains a bare copper wire as the ground. For larger electrical jobs like installing wiring or replacing an electrical panel, expect to pay $2,000 to $6,000. It helps when i am at the parts supplier and want to buy some wire to take to a job site.

The second number indicates the number of conductors. Run the wire or cable to its destination. Can you electrocute yourself by touching an overhead power line to your house?

Maximum operating temperature is not to exceed 90°c in. Electrical work & repair costs. A 100 amp service will need a minimum of 1.25 inches, schedule 40 or 80 pvc grey electric conduit.

This is only applicable for 15 and. A hot and a neutral. Wire and cable your way, your trusted electrical wire and cable supplier.

A wiring diagram is a pictorial representation of an electric circuit, where the elements of the loop and the signal connections between devices and the power source are shown in the conventional methods as simplified shapes. It is a rough guess to be certain. 105 results wire cut type:

Every 3 ft, > 450 ft: Make sure to allow about 2 feet of excess cable at each end. The cable is sunlight resistant and is approved for use in accordance with the recommendations of the national electric code in raceways and underground installations.

Whether it be copper or aluminum, let’s take a look at what size wire you need for a 100 amp sub panel that’s 200 feet away. One of my loose rules of thumb is about one foot per square foot which would be 3 meters per sq meter. A house wiring diagram is thus, a wiring diagram of a house.

Also wrap the hook on the fish tape so it can't snag. You choices are typically 10, 12, or 14 gauge. The second denotes the number of conductors inside the cable.

Get free estimates from electricians near you or check out our pricing. A house wiring diagram is a wiring diagram for any electric. In stock at store today (20) cumberland & nearby stores.

An electrical wire can be the stranded type or a solid form. Strip about 6 inches of outer sheathing from one end of the cable, then hook the conducting wires and bare copper grounding wire through the loop at. The average cost to hire an electrician to install or repair light fixtures, outlets, switches, or fans ranges from $141 to $419 with homeowners spending $280 on average.

• 12 ft above residential property and driveways, and those commercial areas not subject to truck traffic for 120v, 120/208v, 120/240v, 240v, 277v, 277/480v, or 480v circuits [225.18(2)]. The electrical wire can come in rolls or on spools. Remove the covers from the lbs and push a fish tape through the conduit.

You can use a larger conduit if necessary to maintain the inner fill of 40% or less. What is a house wiring diagram? The cable can also be used as direct burial cable.

This may involve fishing it through another wall cavity, or out a small hole drilled in the floor. Strip the wires and attach them to the wall jack. This item 250' 10/2 w/g uf cable.

Insulation is heavy metal free in compliance with. Every 4ft, 250 − 450ft of mainline:

The ground was 2 gauges lighter than the hot and neutral. Heavier more expensive than aluminum copper used in.

Jual Id Heavy Duty Steel Gym Wire Rope Home Cable Machine Fitness Pulley - Jakarta Selatan - Evino Store | Tokopedia

If it's 20 amp, you need to replace the cloth covered wire with 12 gauge to its destination/origin.

When was heavier wire used in houses. I did not want to face doing that again with a new home. A stronger type of wire that meshes should be used along with the chicken wire. A few heavy duty appliances such as air conditioners, electric furnaces or electric water heaters may require heavier gauge wires, are usually 220 volts and are always wired as a dedicated circuit, meaning the furnace has it's own circuit breaker in the electrical panel, the a/c it's own.

For our cabin, we used 12 gauge romex for all of the outlets and lighting circuits. Electrical wire gauge, ampacity, and wattage load Answer:these wires are commonly called romex 1.

For heavier load appliances a larger gauge wire must be used to carry the additional current. If you're adding an outlet, you need to use wire the same gauge as the existing wiring. To find out appliance currents in your house , use this.

10 gauge romex has an orange jacket and is used for water heaters or clothes driers. If the improper gauge wire is used with the wrong size circuit breaker, it can easily result in a fire or a malfunctioning electrical. There are 15 amp and 20 amp circuits.

Usually, triplex aluminum wire was used to run from the power pole to the service entrance weather head feeding your electrical disconnect, that eventually powers your electrical panel in your home. Industrial and commercial wiring must be done in this manner. We stock a complete line of copper thhn/thwn in sizes from #14 to #2.

The largest common type of wire (generally only used for electrical service panels) can carry a maximum current of 95 amps. This 1 big fat wire was used in olden days but is banned now. The house was built in 1985 and i think all of the wiring is 12/2.

When you look at the price of wire at the correct amperage ratings (housing cable or not), you will see a much smaller price difference. It has a cloth outside and some kind of brittle coating over the wire. The outer braid was fabric with only the conductors having plastic or rubber insulation.

Common lighting and plug circuits use #14 wire. I have a house that was built in 1931. These are very important when you consider the constant expansion & contraction of the wire in weather extremes & constant vibrations your vehicle experiences daily that a house never will.

What is a thicker wire on braces used for? It's a single pole switch using a jumper off of the 12/2 wire. 14 gauge romex is still used in some applications and is rated for 15 amps and is grey jacketed.

The smaller the number the heavier gauge the wire. Most homes are wired with a mix of 12 gauge and 14 gauge nmd 120 volt circuits. I need to splice in at a junction box, but i can't figure out if the old wiring is 14 or 12 gauge.

A building/home owner having 1 big fat wiring done could be caught for using it, it’s that illegal. The wire plays an integral role in effectively moving and positioning the teeth, but can often be a source of bewilderment for patients. Yes, you can use chicken or aviary mesh for your rabbit cage but this will not work out well and should only be used in combination with another material such

Similar to nm cables, ac isn’t permitted for use in commercial buildings or residential constructions exceeding three stories. Thhn and thwn wires are now primarily used in conduit systems. Ac wiring is designed with flexible metallic sheathing.

Burial depth for this type of wire is 24 inches. Type “use” wire & uf cable these wires are designed for underground use. Heavier more expensive than aluminum copper used in house wiring 1mm 2 15mm 2.

Also known as bx, this type of electrical wire dates back to the early 1900s, but it’s still in use today. You could possible happen to see it in slum areas but nowhere else. Would there be any issue installing a new bath vent fan where there was not one before with it's own switch, using 14/2 wire on a 15 amp circuit?

Braces use a metal bracket and wire system, sometimes combined with elastic loops, to gradually move your teeth into the desired position over time. This provides extra protection for the conductors inside. Rahulgupta8789 rahulgupta8789 21.09.2019 physics secondary school which wire is used in houses 2

This 1 wire was banned because it was not safe to use and as it was not flexible it would easily get cut when bent. Click to see full answer. Electrical standards were different in 1958.