To flare the pipe, put it into a hole that has a matching size as the copper on the flare form. Flaring tools employ very traditional technology, probably dating back to the earliest metalworking.

Kualitas Tinggi Alat-Alat Pendingin Tabung Kit Alat Flaring Tool/Nilai Flaring Tools Piper Menggunakan Mesin Expander Tube Cutter Chamfering - Buy Kualitas Tinggi Alat-Alat Pendingin Tabung Kit Alat Flaring Tool Nilai Flaring Tools,Piper

Up until the 1980's, 5/8 o.d.

Refirgeration flare different from plubing plare. Clamp the tool onto the tubing. These fittings have traditionally been available in carbon steel, stainless steel, and brass. Hold the flared end on the fitting, and tighten the nut.

While copper tube is usually joined by soldering or brazing, there are times when a mechanical joint may be required or preferred. Tighten the mandrel screw, then loosen and retighten once or twice to fully seat and burnish the tubing. Automotive experts use both the bubble and double flare in brake lines.

If the filler metal melts below 840ºf the process being performed is soldering. But the most commonly used brake line flare is the sae double flare. Cut the tube with a tube cutter.

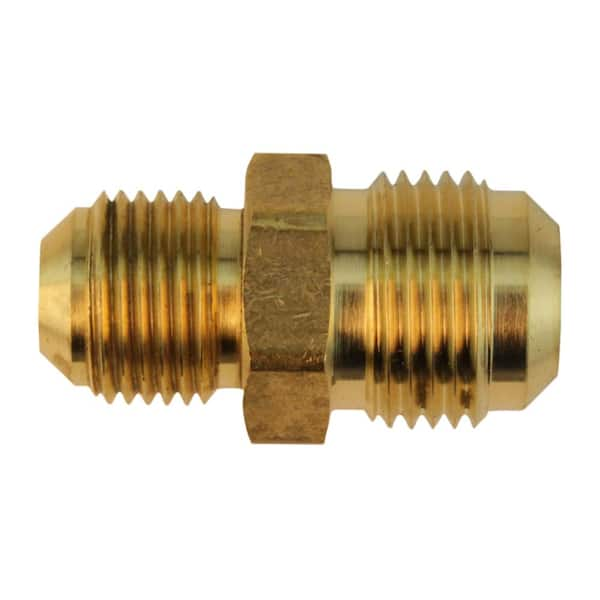

Press/crimp fittings, compression fittings, and flare fittings. 37 degree flare fittings are commonly called an (army navy) or jic. Once the nut is placed on the pipe, a special tool called a flaring tool is used.

Slide the flare nut onto the pipe. It is the tool that does the actual flaring. The basic difference between soldering and brazing is the temperature necessary to melt the filler metal.

Measure the tubing so you can reach the back of the female socket of the flange. Flaring smaller sized copper tubing. Works with steel, copper and aluminium tube, but might be difficult in stainless, unless fully.

Tube flaring is a type of forging operation, and is usually a cold working procedure. 100 mechanical joints tested the experiment. They are used in military, aircraft and race car applications where demands are extreme.

It’s also known as the inverted flare, which is essentially the enhanced variant of the single flare. They are important in both professional and hobbyist applications, making pipe fitting possible. Yellow jackets tool is designed for the 410a flare.samsung ductless instructions talk about the difference of the flare.the flaring tool is worth every dollar it has multiple sizes and set the depth for you its almost too easy.yellow jacket.

Fittings are usually long radius fittings, to reduce pressure drop in the lines, while water fittings are usually short radius fittings, since pressure drop is not usually as critical an issue. Alighn the compression cone on the tubing’s end and tigthen the screw. That temperature is defined to be 842ºf/450ºc by the american welding society (aws) but is often rounded to 840ºf.

When in doubt, double flare. In the attic a 7/8 lineset goes straight from the coil and. As you turn the handle, the cone flares the tubing.

Just about anyone can use them. For low pressures (compared to the tube pressure rating) it makes no difference and makes no difference in therm s of seal integrity. Once it's secured, another tool is put into position that, when screwed down, will deform the pipe, creating a flare.

7.2, rather than releasing them into the atmosphere without burning them, is a more environmentally friendly solution, a great amount of greenhouse gas is released into the environment through. Choose the hole in the flaring block that matches the outside diameter of the flexible copper pipe. They are not common in homeowner products.

The quality of the brake flares is a crucial factor. These fittings have a 37° flare angle and use a class 2a/2b thread, which is a standard tolerance industrial thread with normal trapezoidal root truncation. The longer that copper is kept at the higher brazing temperature, the greater the formation of copper oxide, and nearby valves may be overheated.

Prepare the brazing filler material. Flare systems are elevated to keep the open flame away from ground level and reduce the effects of heat, smoke and noise. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared shape that will form the flare.

9) connect to the fitting: 7) slip the yoke onto the block: Ive leak checked the system in all accessible locations and im sure its in the wall.

These tools don't require much technical prowess; Use a file or the deburring blade on the tube cutter to ream the inside and outside of the tubing. Tub & shower repair parts.

This is also a good time to position the fire cloth behind the joint and dampen anything that can burn with the spray bottle. I have a friend with a system where i am very close to certain there is a leak in the wall which goes up 2 stories to the attic. Above that temperature, the process is.

Center the cone over the tubing. To prevent the formation of oxides and promote bonding to occur between the filler metal and base metal. Although burning hydrocarbons in a flare, as illustrated in fig.

Sliup the flare nut on before you flare the end of the tubing. They also included a brazed joint as a bench mark against the time and leak rate of the various mechanical joints. Flared fittings ( figures 9.1 and 9.2) are an alternative when the use of an open flame is either not desired or impractical.

Use a deburring tool or abrasive cloth to remove any burrs and debris in and around the pipe end. Hd flare tools are likely 45 degree or. Sink repair parts & drainage.

Sae (society of automotive engineer) standardized flare fittings were used for natural gas and propane flexible gas connections. Flare fittings are a type of compression fitting used with metal tubing, usually soft steel, ductile (soft) copper and aluminum, though other materials are also used. No less than tube i.d.

Place the reamer on top of the flare form so the conical point is against the tubing. Slots in the yoke engage the flaring block. Clean the oxides from the tube and the inside of the socket.

Double flare is still thicker than the tube wall and maintains the tube pressure rating. At the exit of the wall near the outdoor there is 1 plumbing copper which continues into the wall with a 90. No less than tube i.d.

Flaring tools are rated by their. Not positive because i rarely go to hd (lowes is close) but chances are stock fittings are 45 degrees. 37 deg tool marks acceptable flare i.d.

A reamer has a conical point, a screw, and holding arms;

P&M 809 Eccentric Flare Tool For Air Conditioning And Refrigeration

Air Conditioning Copper Pipe Extension For Joint Double Connector Intermediate Connection Head Free Welding Butt Copper Tube Diameter 6-19Mm Flare Nut (1/4" (6.35Mm) Copper Tube) : Amazon.in: Home Improvement

Flare Flare Eccentric Refrigeration Piping 6 Die Sizes 1 / 4-3 / 4Inch Taper 45 Degree Eccentric For Copper Brass Aluminum Mild Steel Pipe | Walmart Canada

China Brass Flare Union Double Flare Union With Nut Brass Union Nipple Fitting Coupling Connector Adapter Refrigeration Good Price - China Copper Fittings, Copper Pipes Fittings

Everbilt 1/2 In. X 3/8 In. Flare Brass Reducing Coupling Fitting 801459