If your car doesn't start, you may have a fuel related issue,. This provides power to the code reader.

All-Sun Em4212 Phase Sequence And Motor Rotation Tester,Motor Turn Direction Checker - Buy Motor & Phase Rotation Indicatior Product On Alibaba.com

Because once motor started, the latch (q 0.0) will activate and keep the motor running even after release of test push button.

Tool to tell if motor is turning. To read the code (s) that are causing the “check engine” light to come on. Turning your phone into an obd2 scanner is easy. If by eye the capacitor looks ok it might still be defective.

To perform a cursory check of the bearings, place the motor on a solid surface and place one hand on the top of the motor, spin the shaft/rotor with the other hand. Standard inserts turning inserts employ highly engineered composite structures, coatings, and geometry features to achieve great accuracy and high material removal rates. It should come back to life.

Method 2finding top dead center. Closely watch, feel, and listen for any indication of rubbing, scraping, or unevenness of the spinning rotor. As the engine turns over, look if there is a spark on the test light.

If you suspect the fan motor is bad, the first thing you should check is the power to the motor and the power to the air conditioning unit. Depending on the device, it may prompt you for information at that time. With the diagnostic connector plugged in securely, turn on the ignition.

If you wonder to know how to turn off check engine light by this way, here are 3 steps for you. Unplug the motor from its power source. Actually voltage or current unbalance will produce too much heat thus damaging the motors.

If your tool has a forward and reverse control (as most power drills do), your gear switch may get stuck between the gears. Use a wrench to slowly rotate the motor. If one or two of these signals remain open or closed, one way to optimize the use of a scan tool is to first turn the ignition off, then unplug the transmission range sensor and turn the ignition on again.

To test your dc motor, touch the leads of the ohmmeter to the leads of the motor. Power saw motors have brushes that wear out. Gently move the switch back and forth.

Check the manufacturer’s specifications for maintaining your tool to find out the best method to keep your tool lubed. Use a voltmeter to verify that voltage is being supplied to the sensor from the computer and that the scan tool is reporting all circuits. If there is a small light flashing, it means you are getting a spark.

Using a scan tool is the easiest way for check engine light reset. At that point, the code reader is ready to do its work. The ohmmeter should give different readings as this shaft is rotated (which is.

(make some photos showing the connections so you can make them correctly again, if you need to take them apart.) If the power is fine, check to see if there is proper voltage. Once the motor is up to speed, the start capacitor disconnects and is not used again until the next time the motor starts.

If you suspect that your machine has expired gas inside, exchange it with fresh gas and add a couple bursts of starting fluid to the carburetor; If inspection by eye shows a capacitor that is bloated, burned, deformed, it needs to be replaced. Locate the circuit breaker and ensure it hasn’t tripped.

Any value less than about 0.2 mega ohms is a reason to discard the motor. The tool is plugged into the diagnostic connector (which is usually located under the instrument panel near the steering column). The meter's screen should indicate a low resistance (somewhere between 10 and 30 ohms), but if it reads an infinite ohms or an open circuit you should rotate the end shaft of the motor.

Access the connections between the power cord and the motor windings. To check the condition of the armature windings, the armature will probably have to be removed from the motor. If the start capacitor fails, then the motor will not be.

Depending upon brush size, this may allow access to the commutator without removing the armature from the. Another easy tip for a squealing tool is to check the gears. In less than five minutes, you can troubleshoot your car check the engine light yourself.

You can tell which way the motor is turning as you should feel more resistance if the bell is spinning the opposite direction. Current flowing through this winding produces a rotating magnetic field in the stator that keeps the motor shaft turning after the start winding has turned off. Here is a useful trick to tell which direction the motor is spinning.

Touch one lead to each motor power lead and the other to the metal motor casing. This opens in a new window. Check electric motor start / run capacitors.

Check for shorts and opens. However, if the motor design has external brush holders, you can unscrew the brush caps and remove the brushes. This circular pulley provides power to accessories like your power steering and air conditioning through the serpentine or accessory belts.

Remove the junction box cover plate, if there is one. Here in the above logic, once motor started with test push button, we have to use stop push button for stopping the motor. At the center of the pulley will be a nut.

Test push button nc contact in series with latch Anatomy of a turning tool most turning is done using a replaceable insert that is gripped in a turning tool body, which is then mounted on the lathe turret. Make sure you get a good, secure fit so the tool can communicate with the vehicle's onboard computer.

Check for shorts between the power wiring and ground. In this article, we will show you how to use your iphone or android phone as a. Perform a check of the bearings.

You may need to enter the vin, the type of engine, or other information. Touch the motor bell lightly with a finger when it’s spinning, and let your finger drag across the bell. This might result in unexpected motor failures when critical services from such motors are required affecting availability of plants.

Locate the crank pulley near the bottom of the engine. If your motor uses a start/run capacitor, the capacitor could be defective. If the engine seems like it is hard to start or runs rough, checking the condition of the fuel is one of the easiest fixes you can make.

Configuration Of Turning-Cutting-Force (F) Direction. (A) Overview, (B)... | Download Scientific Diagram

Wanbao 540 Sh 8022 Motor Dc7.4 V20800 Turn High Speed Large Torque Motor Electric Tools|Dc Motor| - Aliexpress

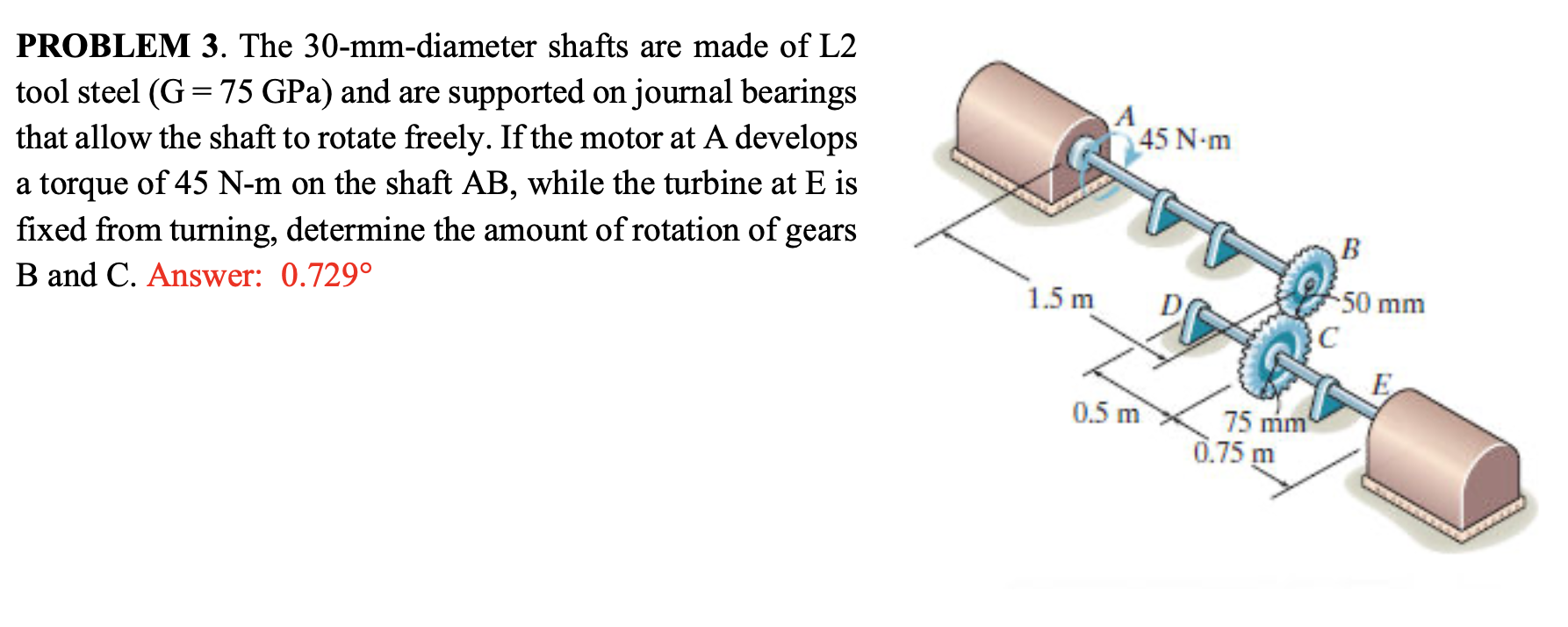

Problem 3. The 30-Mm-Diameter Shafts Are Made Of L2 | Chegg.com

300Kg---600Kg Engine Turning Rack Car Auto Motor Engine Turning Support Platform Lifting Tool Tire Repair Tool - Tire Repair Tools - Aliexpress

How To Check An Electric Motor: 12 Steps (With Pictures) - Wikihow