Energy from the velocity head e vin = 9 e v1. The smallest id on chart 5 is 0.560 in.

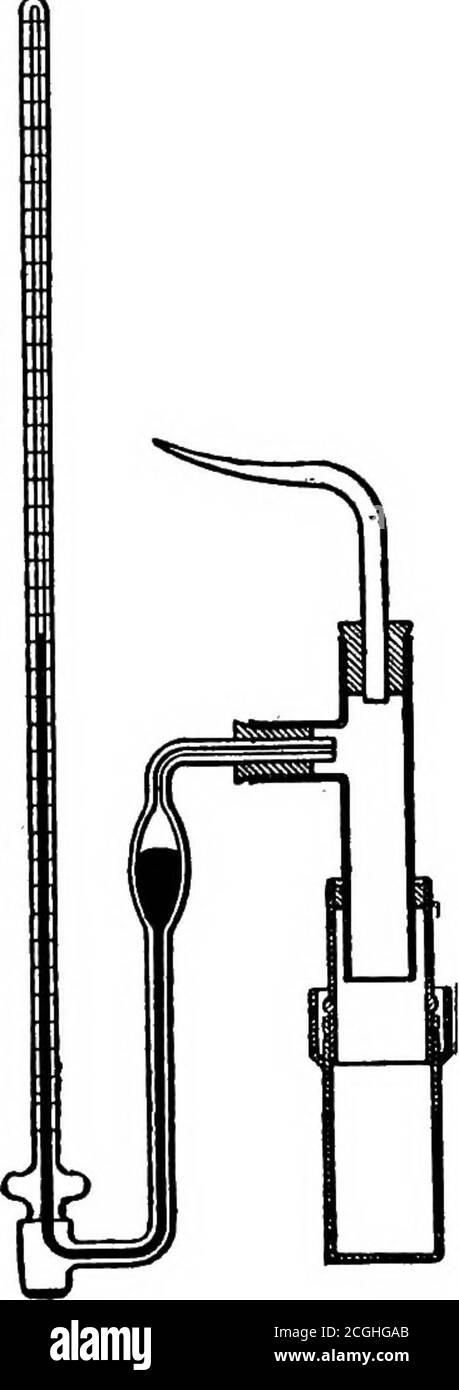

At the top of the bubble tube is where a pressure sensor detects.

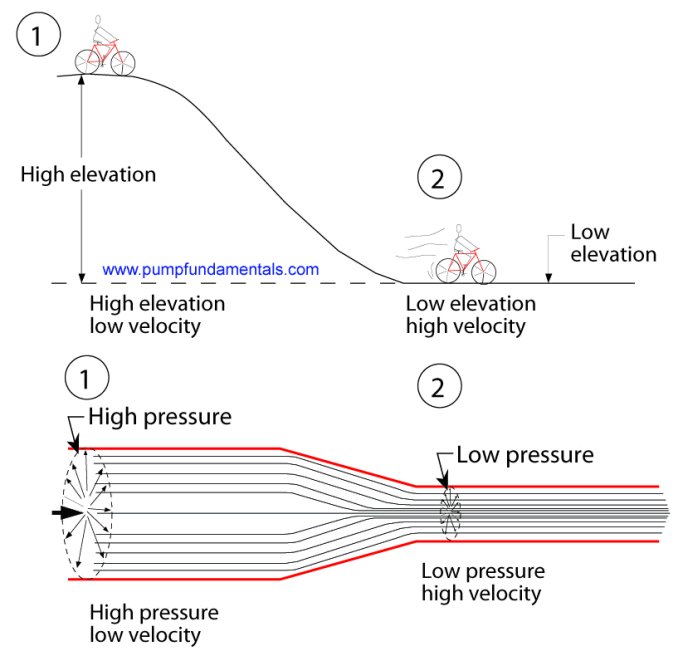

Pressure from large tube to small tube. Pressure monitoring for a constricted tube this is a direct experimental observation of the bernoulli effect. The fluid speeds up when it enters a narrower portion of the tube. The pitot tube is a simple and convenient instrument to measure the difference between static, total and dynamic pressure (or head).

Pressure drop of gasses and vapor. The energy from the dynamic pressure in 9 times as great in. Bernoulli says that since by continuity vin = 3 v 1 = 3v 2 = 3v 3.

Restricting the flow increases the pressure. We expect the pressure drop to be 1 over (⅔)^4.9 or about 7 times higher than the original pipe. Changes in the liquid level cause the air pressure in the bubble tube to vary.

It bends and welds easily. Pressure is maintained as air bubbles escape through the liquid. The problem is that the tube will then foul itself on the carriage or other part of the superstructure of the machine.

Od tubes would be satisfactory. The regime of flow when velocity is lower than critical is called laminar flow (or viscous or streamline flow). When fluid is flowing in a pipe or hose, the pressure will progressively reduce as it moves farther downstream from the pump.

Since it speeds up, it has an acceleration, therefore a net force, in the direction it is moving. Pe d e p z zh h hd ll l,1 ,3 ,4 222 1433 134 134 1.23 2.19 150 ft 30 ft 22 2 llvvlv The water pressure remains the same on both facets of the segment of the pipe.

There is a very persistent misconception in the lawn sprinkler industry that using progressively smaller pipe sizes in a sprinkler system will help keep the water pressure high. Read an overview of how tube and pipe size is measured and handled. Choosing the latter option, keeping in mind that we are ignoring the change in velocity head between points e and d, and noting that the pressure is zero at both points, we find:

The restriction reduces the airflow to a very small amount. P 1 = pressure incoming (kg/m 2) t 1 = temperature incoming (°c) p 2 = pressure leaving (kg/m 2) t 2 = temperature leaving (°c) This net force must result from a higher pressure behind the fluid (in the larger tube portion) and a smaller pressure ahead of the fluid (in the smaller portion.

At laminar regime of flow the velocity is highest on the pipe axis, and on the wall the velocity is equal to zero. That’s about 6 times the original. This is due to less “friction loss” as the water flows through the larger size pipe.

However, thanks to friction, the smaller pipes have more resistance towards water than larger pipes. At flow rate of 1 gpm. The argument is that as the water moves through the pipes past the sprinklers, the pipe must get smaller in order to squeeze the water so.

Od tubing can be used because the pressure drop would be over 10 psi for a 4 gpm flow in smaller tubing. At 0.6 gpm, the pressure drop is 7.5 inches, about 7 times the original. The short answer is that the larger pipe would be better because there would be less pressure loss in the pipe.

Outlined below is a simple procedure for optimizing tube size to maximize system performance. If the bend has a large enough radius and/or if the tube diameter is small enough then there will be enough flexibility to allow the tube to be lifted up and over any part of the machine and avoid the fouling. The narrower the pipe, the higher the velocity and the greater the pressure drop.

A smaller pipe may create more friction loss however, so it. Discussion of od and nominal pipe size as well as wall thickness and pipe schedule. Through pipes 1, 2, and 4, or that through pipes 1, 3, and 4;

This tube is formed through rollers from flat strips into round tubes and welded into a solid piece. The variations in pipe diameter will not affect the static pressure. Compressible fluids expands caused by pressure drops (friction) and the velocity will increase.

16 votes) “in a water flowing pipeline, if the diameter of a pipe is reduced, the pressure in the line will increase. A tube that is too large unnecessarily increases costs and is more difficult to fit in tight spaces. At 0.3 gpm, the pressure drop is 3 inches.

The pressure will be determined by moving from point a to point b: Assuming the water is flowing fairly steadily, then it will be moving at a higher speed in the smaller diameter. Continue reading using a smaller pipe to increase water pressure →

Hot rolled electric welded tube, 1015 steel alloy. Because the narrow section is a restriction. From bernoulli’s equation, the pressure would be lower in the narrow section.

If a u shaped glass tube is half filled with a liquid, e.g. Basically, when water accelerates from. Head to velocity online calculator.

The water flow is slower in the bigger pipes, but water pressure will increase. In pipes with a small size, water flow is faster as compared to bigger pipes. An id of 0.560 in.

The larger amount of water in the bigger pipe has no impact on the water pressure. 3/4” pex has a pressure drop of 0.34 gpm per 100 ft. This a fact that refutes the widespread belief even if you reduce or increase the size of the pipe.

A high pressure air supply directs air through a glass tube which has a constriction about halfway along it. The material can include several alloying elements (for example, up to 0.4% chromium and 0.15% molybdenum, but as little as 0.0% of both). Pexuniverse gives nominal pressure drosp in psi per 100 ft.

Although probably the oldest method of measuring low pressures, the simple u tube has much to commend it. The simplestvway to view this is as follows. Therefore is the pressure drop along the pipe not constant.

For each nominal pipe size, the outside diameter (o.d.) remains relatively constant; Bernoulli's theorem says that there should be a reduction in pressure when the area is reduced. A tube that is too small can increase fluid velocity causing pressure drops and heat generation, and in suction lines, pump cavitation damage.

As the pressure builds, bubbles are released from the end of the bubble tube. Pressure drop when using a smaller pipe size. When the velocity is greater than critical, the regime of flow is turbulent.

From chart 5, for 4 gpm flow rate, the pressure drop per 100 feet of any of the 3/4 in. Pressure is indicated by three manometers in which the liquid level is a measure of the pressure above the liquid. Of tubing length for several flow rates from which we excerpt below.

In turbulent regime of flow there is. And at 0.9 gpm, we’re off the scale. Water, and a pressure is applied to one end of the limb, the other being open to

These principles seems reasonable as a first approximation. The pipe size and water pressure: 1/2” pex has a pressure drop of 1.70 gpm per 100 ft.

Introduction To Inorganic Chemistry . His Would Indicatea Pressure Of 760 X 0.7 -I- 1.03, Or 616 Mm.(0.68 Atmospheres). In Practice A Small Bent Tube Opening Intothe Cylinder Is Used As

Water Of Density Pw Flows From A Large Pipe Of | Chegg.com

Condensate Recovery Piping | Tlv - A Steam Specialist Company (Middle East)

A Pipe To Flow Water. The Velocity Of Water In The Big Pipe Is 36 Km/H... | Download Scientific Diagram

Solved 7 4 Points Gasoline (Sg=0.67) Is Flowing A 0.11 M^3/S | Chegg.com