Allow the pressure to increase to 1.5 times the normal operating pressure. Then testers hold the hose under water for at least one minute while looking for bubbles.

Brass Refrigerant Testing Manifold Gauge W/ Hose And Attachable Hook - Testing, Charging, And Evacuating Air Conditioning - R12 R22 R404A R134A | Lazada Ph

The least expensive and most common type of recharging kits are freon cans.

Air charging hose testing. In my book just needs a recharge: Risk leaving a leak at the schrader cores and caps The purpose of this test is to.

Watch the gauge on the refrigerant hose and check to see if your pressure is under 40 psi. The hack mechanic™ guide to vintage air conditioning, i make the case that those “a/c recharge $79.95” signs you see at service stations are perilously close to fraud. You want the reading as close to 40 psi as possible.

When you test your hoses, a hose rupture can occur. When the vacuum holds, the plant is ready for charging. These are just ball park number ranges to get you close, units should be charged in accordance with.

One minute, visually inspect hose and couplings for any leaking or unusual conditions. Couple a refrigerant cylinder to the liquid line charging valve, making sure that the cylinder is slightly tipped towards the head, and that it is lying the correct way for the bent internal discharge pipe to be at its lowest point. When a clutch comes loose or a hose breaks while under pressure, a hose can become wild.

Make sure you get air out of your refrigerant gauge hoses before charging a air conditioning unit. Adherence to best practice in service, maintenance leak testing and repair can significantly reduce refrigerant losses. This results in the following dangers:

Accurate and repeatable measurements for reliable results of leak testing A hydrostatic test uses water at a higher pressure inside the hose to verify the structural integrity of the end weld connections. Unit 3, the crosshouse centre, crosshouse road, southampton, so14 5gz (all telephone calls are recorded)

Until the pressure on the hose is adjusted, it is a great danger. Impulse testing for hydraulic hose is one of the key predictions of hose life. Surieen r410a ac refrigerant charging hose kit, r410a r134a r502 r22 r12 r404a manifold gauge hose ac charging testing kit, with r410a straight swivel adapter, 1/4 male to 1/2 female tank adapter 4.3 out of 5 stars 62

Checking the system (and charge) without gauges. Frequent testing at a too high test pressure is destructive and can result in the connection between the inlays and the hose being broken. Impulse testing involves the pressurizing or cycling of hose pressure, often times up to 133% of working pressure, at rates up to 1 cycle per second while the hose is held in either a 90° or 180° configuration.

Instant access to charge air cooler (cac) application experts. A leak test is performed to identify weak spots as well as to improve product design. Hold pressure at the working pressure long enough to check for leaks and perform any measurements.

If a system needs to be recharged, it’s because the refrigerant has leaked out, so the leak first needs to be found, then needs to be fixed. In generally they usually work the same way across the. Leak rates do not have to be this high.

We get more accurate readings when we connect gauges, but we also: Identify the weak spot of a pressure component. With the air bleeder open, the pressure shall be raised gradually to 45 psi (± 5 psi) (3.1 bar ± 0.35 bar or 310 kpa ± 35kpa) 12.

Reduced time to market and new part introduction. Immediate response with full design support. Make sure charging hose connections are secure.

After the hose test layout is full of water, all the air in each hose line shall be exhausted by raising the discharge end of Shorter lead times for ‘at speed’ and ‘on time’. Meet budget targets for lifecycle cost of product.

Benefits of goodflex charge air cooler (cac) hoses. Conditions appear contact the appropriate person for disposition of the hose. Testing the integrity of the hose to the outside, i.e.

To pass the test, the hose must meet or exceed two. Feed a small amount of refrigerant through the gauge test line and the charging line to purge any air. My question to you is, what do you think is in a system that has a leak and all of t.

Then inspect the hose and couplings for tightness. [note that newer test equipment may provide other solutions for this step to avoid releasing any refrigerant to the atmosphere.] then tighten the connection of. This guide shows you how.

Always make sure you follow the specific directions on the ac charging system. The pressure test must take place with water with the hose outstretched. Benefits of leak testing ac hoses with tracer gas.

For those of you worried about using compressed air because of moisture. The test is performed by using high pressure to check if there is a pressure drop caused by an unintended crack or hole. These often come with small hoses and gauges attached for an easy diy job.

Check if refrigerant may leak to the outside by charging both lines with helium and detect the presence of helium in the vacuum chamber. Risk contaminating the system with moisture and air; Particularly when the hose is large in size or when a part is still attached.

Determine min and max burst pressure.

Jual Ac Diagnostic Manifold Gauge Set,Hvac Diagnosti Tool For Auto Household R22 R134A R404A R410A Refrigerant,5Ft Hose Adjustable Quick Coupler Indonesia|Shopee Indonesia

Business, Office & Industrial Hvac & Refrigeration: Gauges & Probes Suneducationgroup.com Hvac A/C Refrigeration Test Charging Manifold Gauge Set

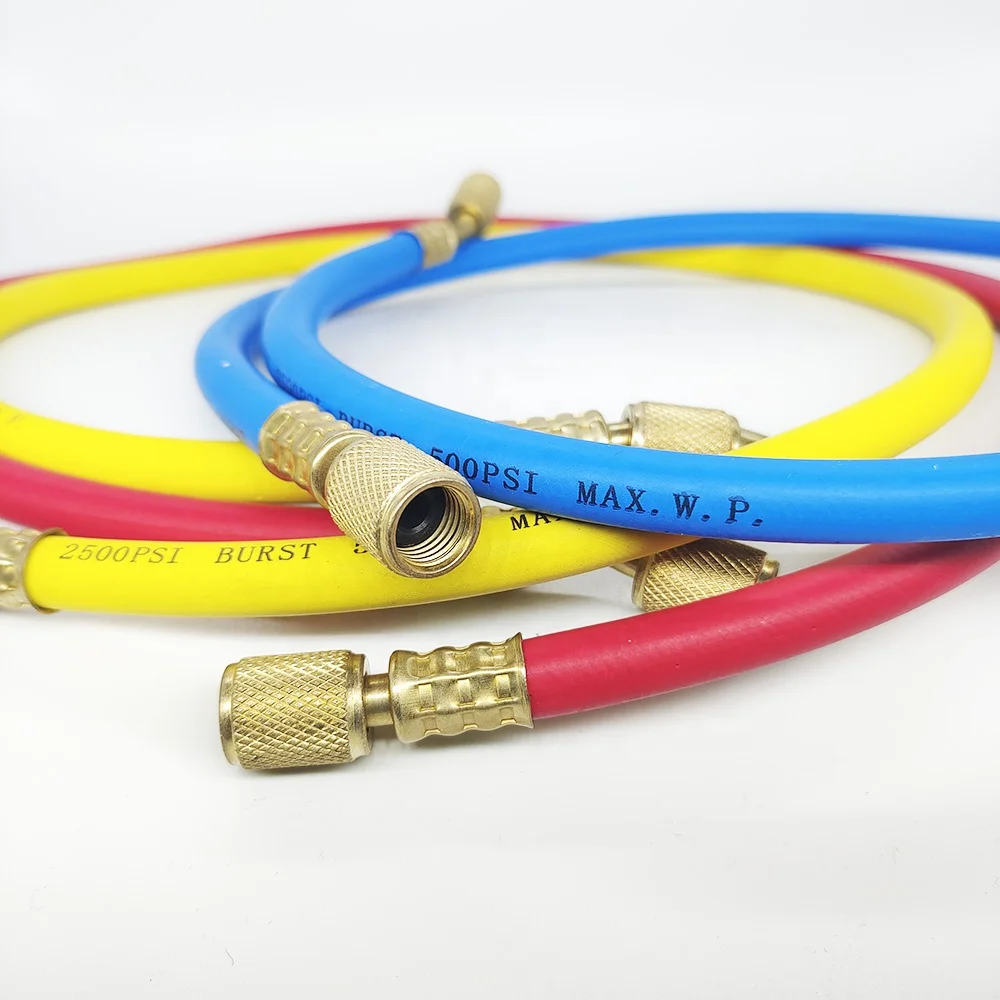

Ct-336A Charging Hose R134A R22 R410 Charging Hose Refrigerant - Buy Charging Hoses Ac,Refrigerant Charging Rubber Hose,Ammonia Charging Hose Product On Alibaba.com

Car Air Conditioning Refrigerant Recharge Test Hose Gauge Kit For R134A R22 R12 | Ebay

3Pcs/Set New R12 R22 R502 Automobile Air Conditioner Refrigerant Charging Hose For Car Auto A/C Refrigeration System|Hoses & Clamps| - Aliexpress